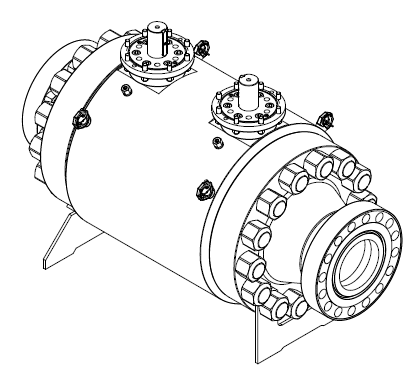

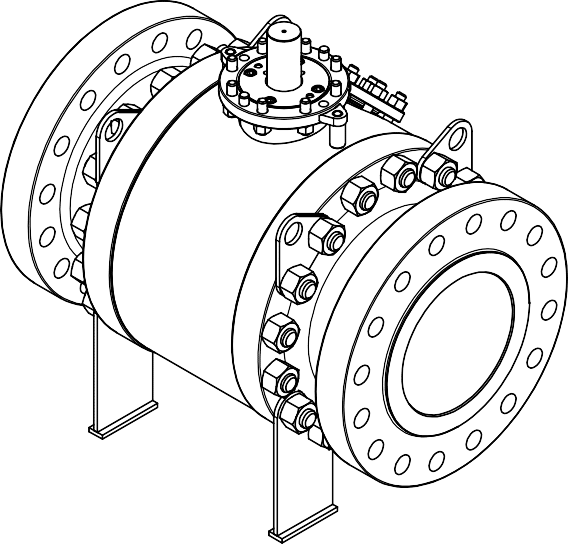

TRUNNION (Side entry)

The ball is mounted on a trunnion plate which supports the pressure load. The seats are spring energized, to allow tightness at low pressure, while the seats are energized by the pressure itself at high pressure. Body construction is three pieces, bolted joint, made by forging, forged or rolled bar.

| STANDARD DESIGN | API 6D |

| BODY JOINT | Split Bolted Body |

| FACE TO FACE | Face to Face and End to End dimension as per API 6D or ASME B16.10 |

| END CONNECTION |

|

| PORT | Full or Reduced Bore |

| RANGE SIZE | Nominal Ball Bore 6” ÷ 60” |

| RATING CLASS DESIGNATION | From 150# to 2500# |

| DESIGN |

|

| VALVE STANDARD FEATURES |

|

OTHER PRODUCTS

Fully Welded

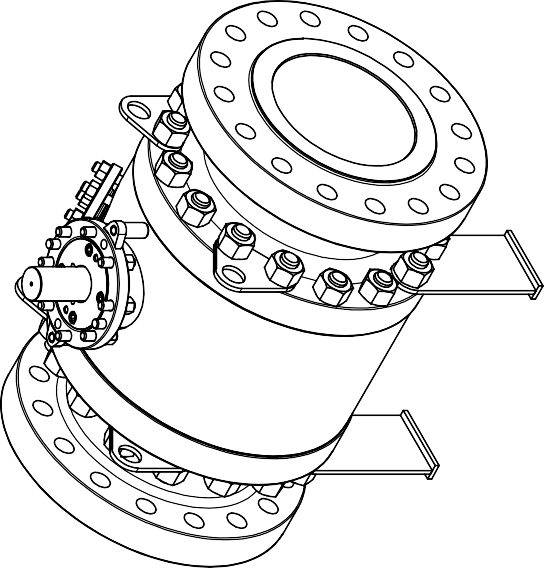

TRUNNION (Side entry)

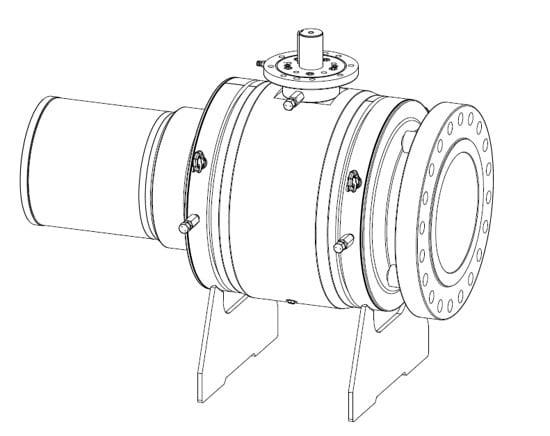

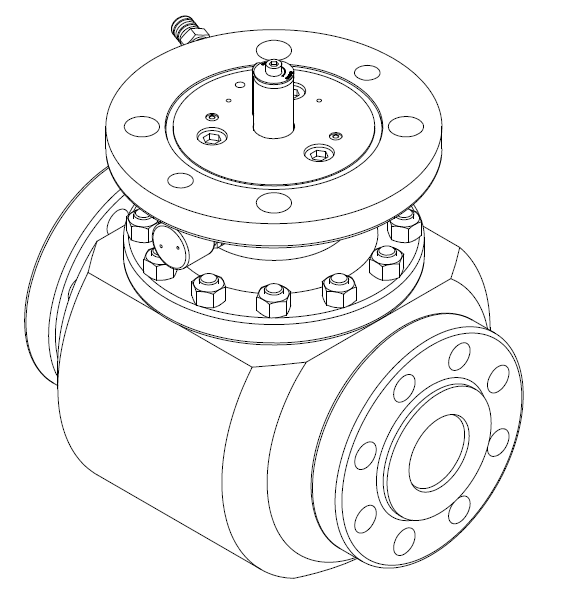

TOP ENTRY

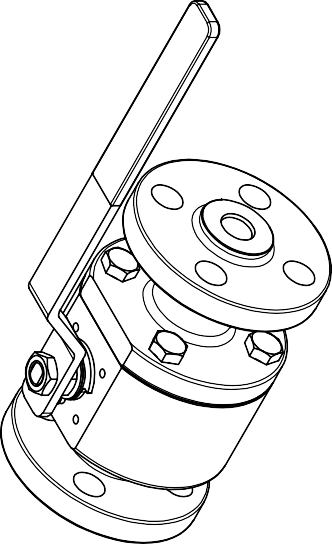

FLOATING

MODULAR DB&B