VALVES

The ball valve is the most common and widely used type of flow shut-off device. Its operation is based on the 90° rotation of a spherical ball equipped with a cylindrical cavity coaxial to the flow. The valve allows closing, opening and reducing the flow.

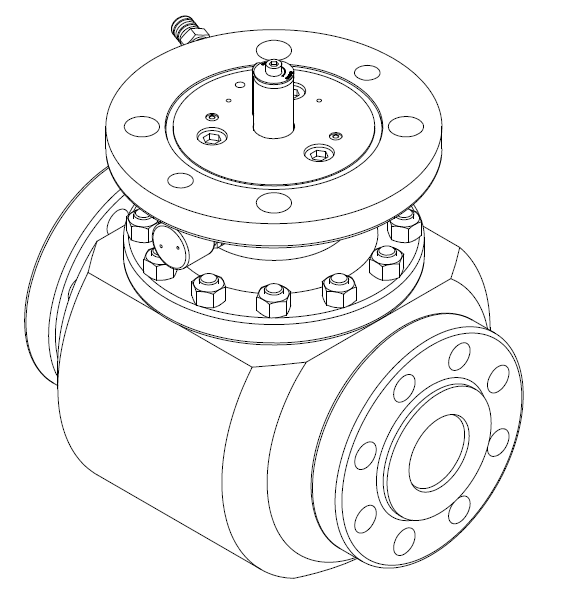

TOP ENTRY

The ball is mounted on a pin that supports the pressure load. The seats are spring energized to allow sealing at low pressure, while the seats are energized by the pressure itself at high pressure. The body construction is one-piece, made by forging or casting. The ball is inserted from above, and the valve can be disassembled inline.

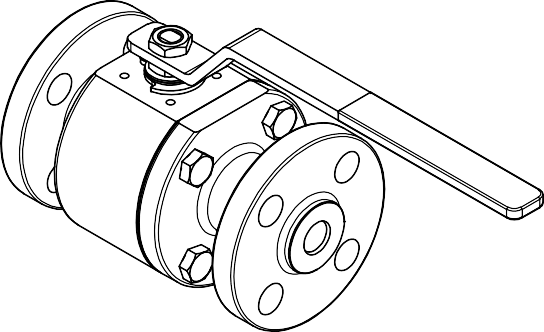

FLOATING

The ball is not held rigidly on its axis of rotation and thus is free to float between the seat ring. Achieving tightness by the action of pressure, which pushes the ball against a seat ring. The body construction is two-piece, bolted joint, made by forging, forged bar or rolled.

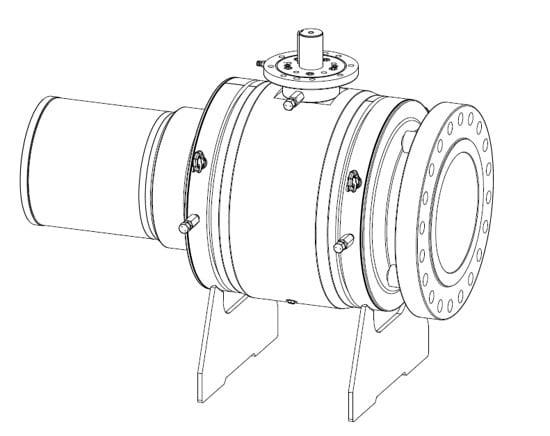

FULLY WELDED

In fully welded ball valves, the body and closures are welded together; the result is a solid assembly with no leakage paths. This application is an ideal solution when there is no maintenance on the valves or when a buried solution is being considered

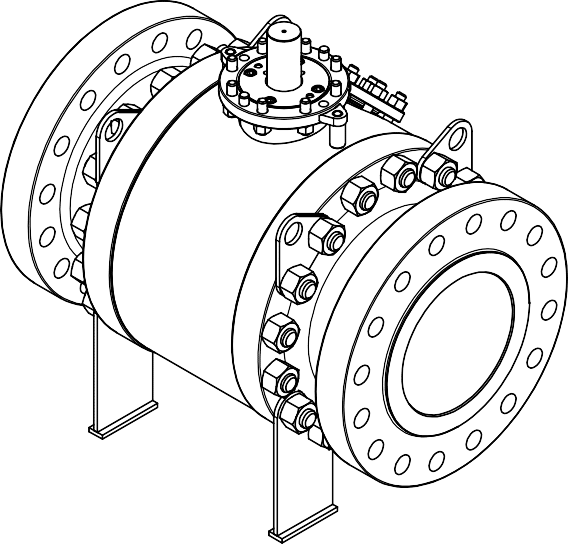

TRUNNION (Side entry)

The ball is mounted on a trunnion plate that supports the pressure load. The seats are spring energized to enable sealing at low pressure, while the seats are energized by the pressure itself at high pressure. The body construction is three-piece, bolted joint, made by forging, forged bar, or rolled.

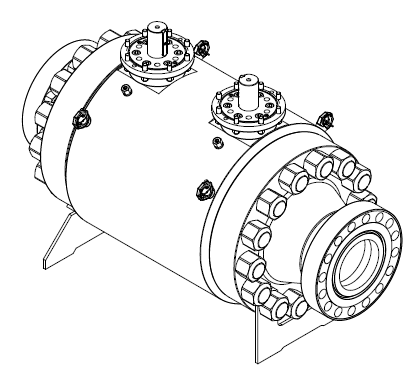

MODULAR DB&B

The valve design can be Trunnion Mounted or Floating Ball. The DBB feature is aimed to achieve a double barrier on the pipeline and to leak fluid between two balls from the body cavity through a valve or pipeline. The body construction is in three pieces, made by forging, forged bar or rolled.