VALVES

Our machining company has a state-of-the-art machine park, including state-of-the-art CNC machining centers, automatic lathes, EDM machines, and laser cutting systems. Our equipment is continuously upgraded to ensure the highest precision and quality.

We are committed to promoting sustainable practices and minimizing the environmental impact of our operations.

We invest in eco-friendly technologies and take measures to ensure the safety and well-being of our employees.

We collaborate with major national and international companies, providing customized solutions that meet specific customer needs. Our network of partners and suppliers enables us to offer high-quality services globally.

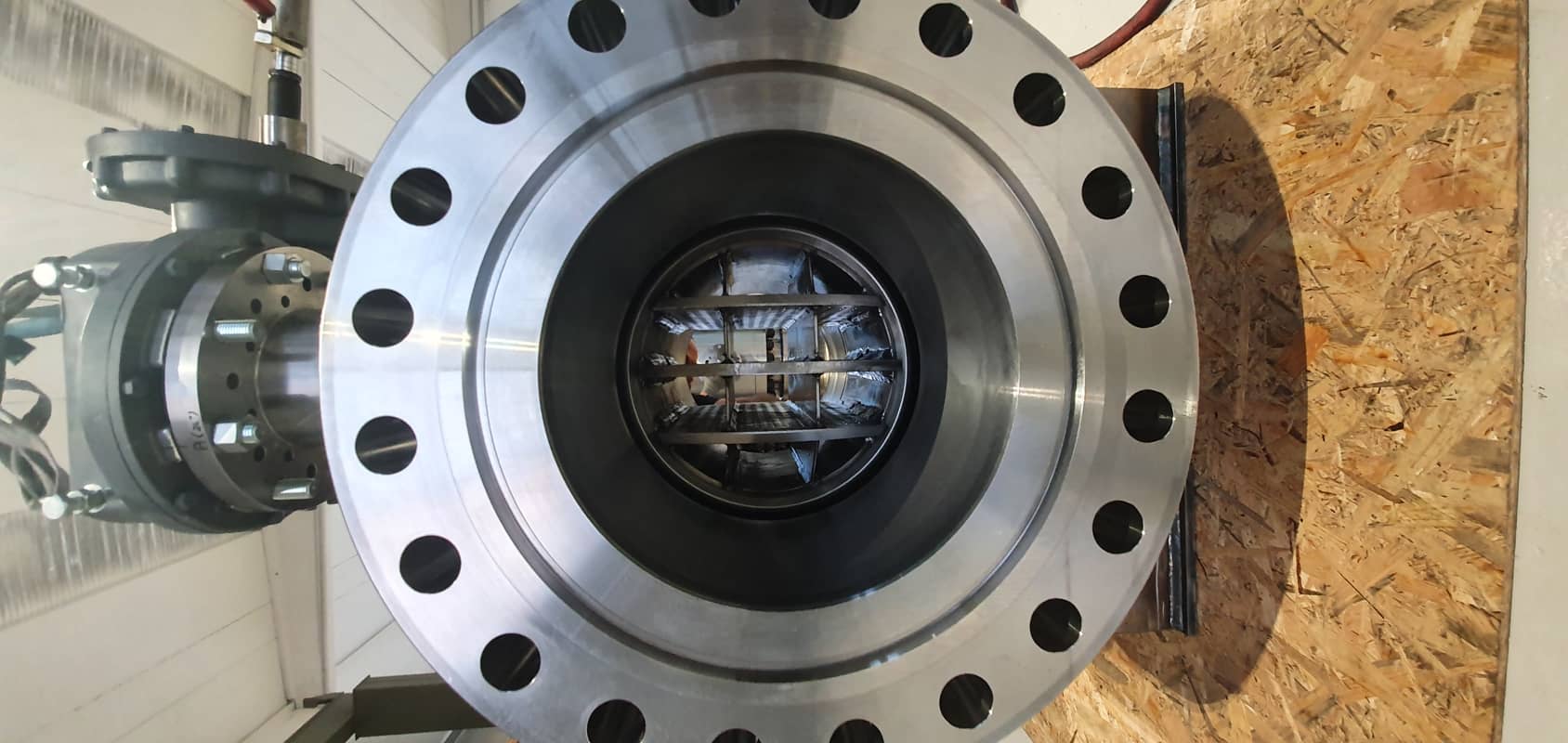

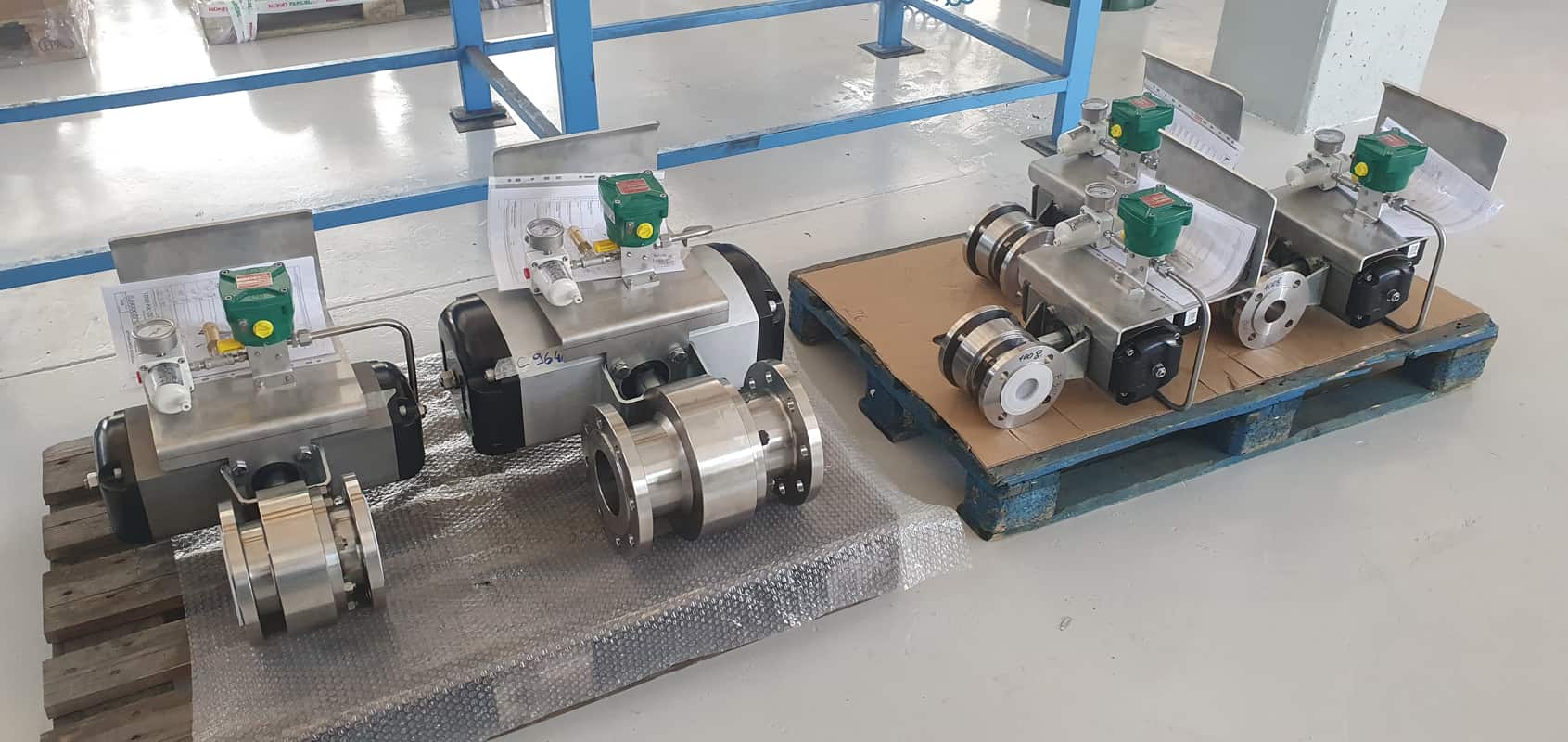

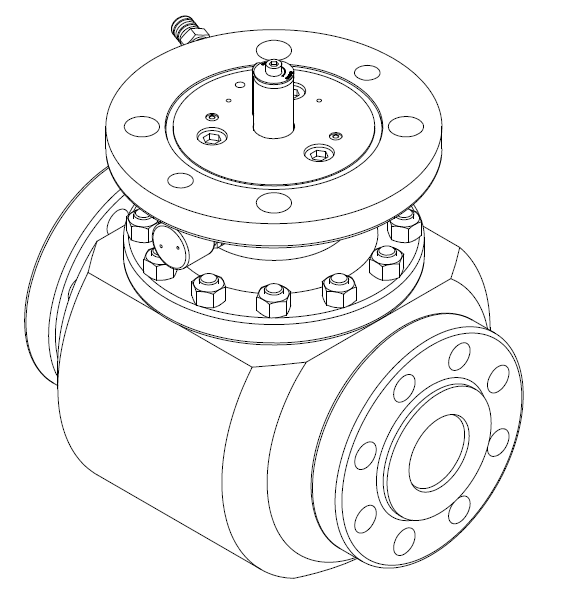

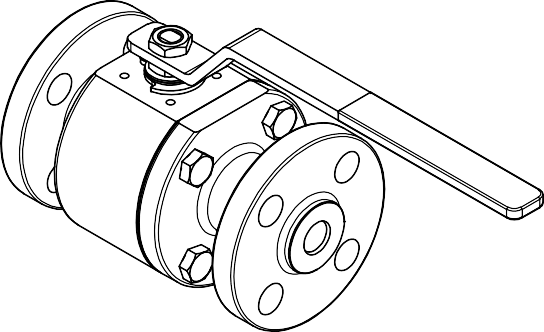

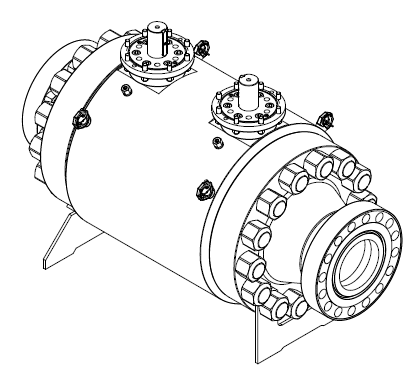

LCI can supply customers with various diameters, pressures and materials of ball valve components, size: 1600mm, pressure: 150LB-4500LB and API10K”, main materials include: A105、LF2、 410、F6A、4130、4140、F304、F316、17-4PH、F51、F53、F55、F60、F44, Monel, Inconel, Titianium, etc.

Our growth path is characterized by technological innovations and a continuous commitment to improvement.

Our team consists of highly qualified and experienced professionals in the field of machining. Our workforce is our most valuable asset and we are dedicated to their professional and personal development.

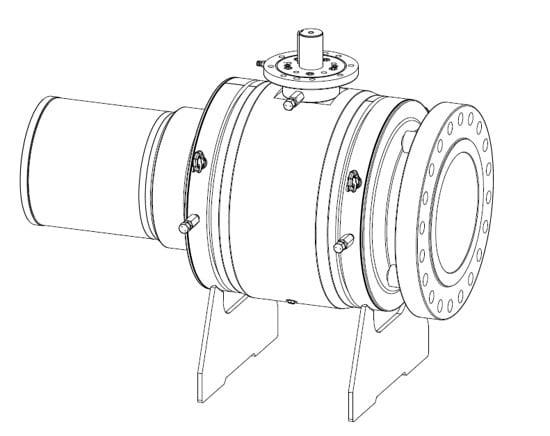

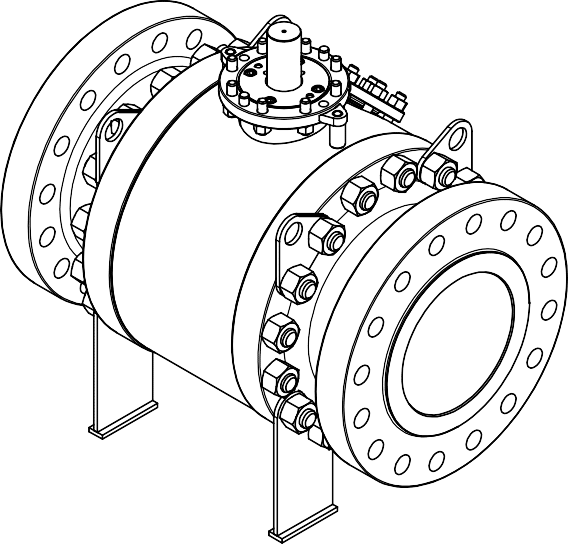

Fully Welded

TRUNNION (Side entry)

TOP ENTRY

FLOATING

MODULAR DB&B

GALLERY

LCI VALVE COMPONENTS S.R.L.

VIA KENNEDY, 3/5 3/5 – 20023 – CERRO MAGGIORE (MI) – IT

P.IVA: IT09160290962